• Made from our BSP polymer with dynamic memory, specifically engineered to absorb impacts and then immediately return to its original shape

• Light and easy to install

• Color: Std. Yellow, other colors available

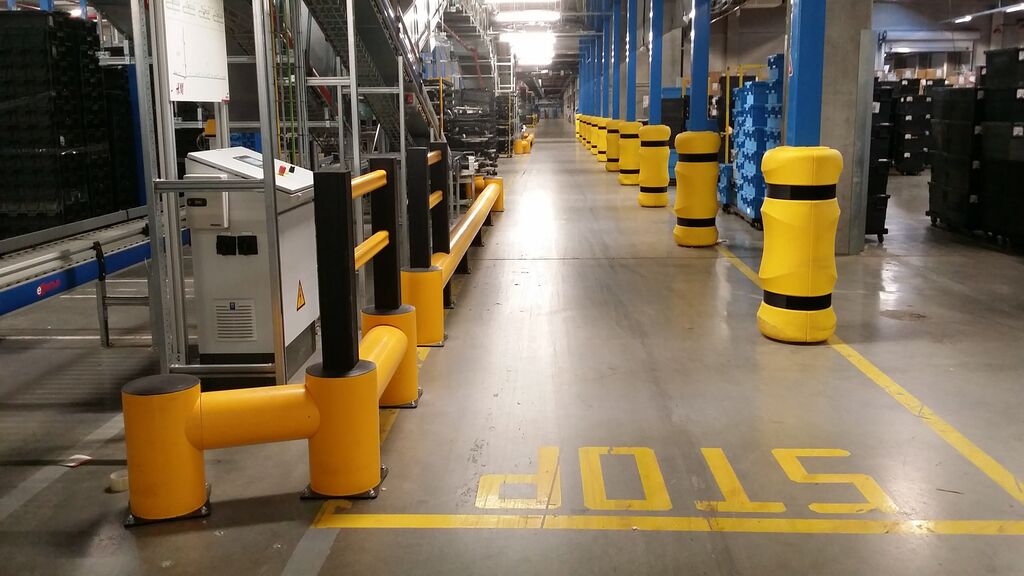

Boplan KP Protector Flex Impact Column Protection

The KP Protector is a round column protection for round load-bearing pillars or for columns with an H beam. This pillar protection helps you prevent collision damage to masts and load-bearing pillars and columns in factories and warehouses. The KP Protector consists of two parts which you can easily snap shut around the pillar.

The KP Protector belongs to the FLEX-IMPACT® family and, like the other products of this series, is extremely impact-resistant. It meets and absorbs the impacts with the slightest of collisions. This durable synthetic pillar protection is available in a variety of colours and sizes and is maintenance-free. After impact, this pillar protection retains its shape, appearance and characteristics.

They are available in different sizes to fit different needs. However, for smaller and non-standard sized columns, we offer this additional foam fill-up. This optional foam fill-up accessory adds extra shock absorption properties and can be used to allow you to perfectly fit your KP Protector to smaller columns, pillars and masks. This performant foam offers added resistance against impact and maximises the effectiveness of your KP Protectors in high-risk areas, or where your columns are of a non-standard size.

KP Protectors have two installation options. This allows them to be fitted to different sized pillars to offer maximum protection. By rotating the angle of the KP Protector slightly, different recesses become available to fit your column more effectively. This feature maximises the benefits provided by the KP Protector by ensuring a better fit to your column. The KP Protectors are easy to install and can be fitted to all sizes of columns, pillars and masts.

Technical Specs

Features

ACTIVE MEMORY

FLEX IMPACT® has been specially designed to absorb the force released in a collision with a heavy vehicle. In the event of a collision, the material simply bends and then returns to its original shape again afterwards.

EASY TO USE MODULAR DESIGN

Various modular building blocks can be used to compose a variety of configurations. The locking method doesn’t require screws or bolts, allowing certain freedom of movement between connecting elements. A fixed locking method would increase the risk to break upon impact.

LIGHTWEIGHT COMPARED TO STEEL

FLEX IMPACT® safety products are much lighter and therefore much easier to transport than their classic counterparts in steel. One might expect light materials to be weaker, but that is far from the truth.

STRENGTH EQUIVALENT TO STEEL

The flexible polymer used in our FLEX IMPACT® safety products is at least equal to the classic steel safety solutions that have been outpaced by modern technology.

LONG LIFESPAN + LOW MAINTENANCE = COST SAVING

FLEX IMPACT® crash protection requires little to no maintenance. In addition, due to the impact resistance, the costs of restoration and replacement will be kept to a minimum.

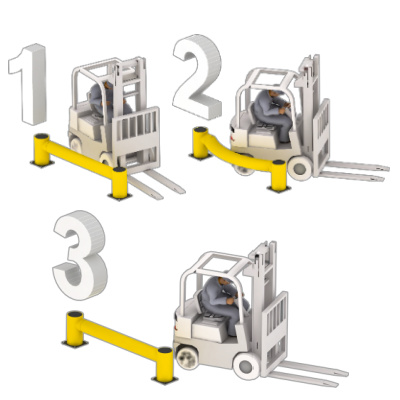

NO FLOOR DAMAGE

When colliding against one of our FLEX IMPACT® safety products, the force of the impact will be absorbed by the flexible polymer and subsequently distributed throughout the entire volume of the safety post or safety fences. The force of the impact will therefore no longer be focused on the base. This ensures that the FLEX IMPACT products will last much longer and withstand collisions far better without damaging the floor.

TESTED AND APPROVED

In the execution of the safety tests, we work in close collaboration with highly recommended partners, such as Transpolis L.I.E.R. laboratories. When the tests produce a successful result, these authorities grant us their certification and label.

GET IN TOUCH WITH US

Do you have questions or would like to talk to one of our consultants? Get in touch with the form below or give us a call.

"*" indicates required fields