Understanding the Differences Between Safety Barrier Systems

From safety to convenience, industrial safety barriers protect workers and pedestrians from workplace hazards and heavy machinery traffic. But do you know what separates different kinds workplace barriers from each other? The truth is, not all safety barriers serve the same purposes or functions. Knowing who and what you may need barrier systems for – and what kind of barrier systems exist to meet those demands – is essential for a safe workplace.

Continue reading to learn the important distinctions between different safety barrier systems.

Who are workplace safety barriers for?

Safety barriers serve a variety of purposes, protecting different people from different things.

1. Hazard barriers

Workplaces contain many different hazards, from blind corners to falling objects to dangerous chemicals. Safety barriers can be used to physically direct workers or pedestrians away from potential hazards, or can be used simply to identify them and prompt heightened awareness.

2. Machinery barriers

Areas where heavy machinery is in use often require sturdier safety barriers. Machinery barriers must have the strength to withstand the force of accidental impacts by machinery. Forklifts that mistakenly reverse too far or runaway palette trucks could be very dangerous to those nearby. Machinery barriers are often used to isolate areas where machines are in heavy operation.

3. Pedestrian barriers

Working in public spaces presents a whole new set of challenges. Pedestrians are not trained to navigate the dangers of your working environment and need to be kept well clear of any potential hazards. Pedestrian barriers are usually erected around the perimeter of a work area to keep pedestrians at a safe distance.

What kind of safety barriers are available?

You know who your barrier systems need to protect. Now, what kind of safety barrier will best protect them? Here are a few options.

1. Bollards

Bollards, short (usually waist-high) posts erected in rows, were once used for the mooring of boats, but today are frequently used as safety barriers. Bollards can be particularly effective because pedestrians can pass between them easily, while cars and other machinery cannot.

2. Cones

Cones, also called pylons, are easy to handle and rearrange, making them a viable temporary barrier solution. Cones can hardly be counted on to physically stop a hazard, but they can effectively guide workers and pedestrians away from dangerous areas.

3. Marking Tapes

Brightly coloured, often reflective marking tape is often considered in areas where hazards exist, but free movement is necessary for either safety or efficiency.

4. Steel Barriers

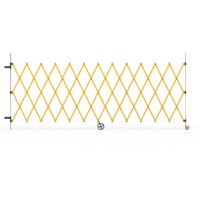

- Expandable Barriers – Expandable safety barriers are ideal for high flow areas where foot traffic is high, but where machinery must also come and go.

- Machinery Barriers – Forklift barriers are specially designed to withstand the force of errant machinery. Their broad sides keep workers safe and effectively prevent accidents.

- Pedestrian Barriers – Pedestrian barriers are slightly lighter physical barriers, designed to segregate pedestrians from areas of heavy machinery.

Find the right safety barrier system for you

If you’re looking for quality steel safety barriers, DexSafe has the options to fit your needs with a range of barriers designed to meet the safety demands of many industries. Contact DexSafe today to the take the next step toward a safe and secure workplace.